A heat exchanger is a device built for efficient heat transfer from one medium to another, whether the media are separated by a solid wall so that they never mix, or the media are in direct contact.[1] They are widely used in space heating, refrigeration, air conditioning, power plants, chemical plants, petrochemical plants, petroleum refineries, and natural gas processing. One common example of a heat exchanger is the radiator in a car, in which the heat source, being a hot engine-cooling fluid, water, transfers heat to air flowing through the radiator

Types of heat exchangers

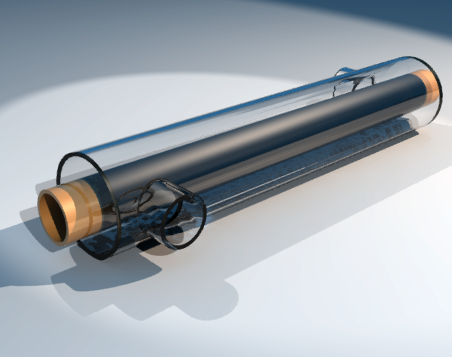

Shell and tube heat exchanger A Shell and Tube heat exchangerMain article: Shell and tube heat exchangerShell and tube heat exchangers consist of a series of tubes. One set of these tubes contains the fluid that must be either heated or cooled. The second fluid runs over the tubes that are being heated or cooled so that it can either provide the heat or absorb the heat required. A set of tubes is called the tube bundle and can be made up of several types of tubes: plain, longitudinally finned, etc. Shell and Tube heat exchangers are typically used for high pressure applications (with pressures greater than 30 bar and temperatures greater than 260°C.[2] This is because the shell and tube heat exchangers are robust due to their shape.There are several thermal design features that are to be taken into account when designing the tubes in the shell and tube heat exchangers. These include:

Tube diameter: Using a small tube diameter makes the heat exchanger both economical and compact. However, it is more likely for the heat exchanger to foul up faster and the small size makes mechanical cleaning of the fouling difficult. To prevail over the fouling and cleaning problems, larger tube diameters can be used. Thus to determine the tube diameter, the available space, cost and the fouling nature of the fluids must be considered. Tube thickness: The thickness of the wall of the tubes is usually determined to ensure: There is enough room for corrosion That flow-induced vibration has resistance Axial strength Ability to easily stock spare parts costSometimes the wall thickness is determined by the maximum pressure differential across the wall.

Plate heat exchanger

Main article: Plate heat exchangerAnother type of heat exchanger is the plate heat exchanger. One is composed of multiple, thin, slightly-separated plates that have very large surface areas and fluid flow passages for heat transfer. This stacked-plate arrangement can be more effective, in a given space, than the shell and tube heat exchanger. Advances in gasket and brazing technology have made the plate-type heat exchanger increasingly practical. In HVAC applications, large heat exchangers of this type are called plate-and-frame; when used in open loops, these heat exchangers are normally of the gasketed type to allow periodic disassembly, cleaning, and inspection. There are many types of permanently-bonded plate heat exchangers, such as dip-brazed and vacuum-brazed plate varieties, and they are often specified for closed-loop applications such as refrigeration. Plate heat exchangers also differ in the types of plates that are used, and in the configurations of those plates. Some plates may be stamped with "chevron" or other patterns, where others may have machined fins and/or grooves.

Regenerative heat exchanger

A third type of heat exchanger is the regenerative heat exchanger. In this, the heat (heat medium) from a process is used to warm the fluids to be used in the process, and the same type of fluid is used either side of the heat exchanger (these heat exchangers can be either plate-and-frame or shell-and-tube construction). These exchangers are used only for gases and not for liquids. The major factor for this is the heat capacity of the heat transfer matrix. Also see: Countercurrent exchange, Regenerator, Economizer

No comments:

Post a Comment